Quantum Sensing for Zero-Defect Manufacturing

Achieve Zero-Defect Manufacturing. See What Classical Sensors Miss.

Quality control failures in high-stakes environments like aerospace and automotive.

Traditional Non-Destructive Testing (NDT) misses the micro-defects in advanced composites and battery cells that lead to catastrophic failure.

A specialized advisory and implementation track focused on next-generation quantum sensors.

Achieve zero-defect manufacturing and navigation resilience. We implement the sensing technologies that see what classical sensors miss.

Battery Health Monitoring

Implement Nitrogen-Vacancy (NV) center sensors to detect minute magnetic anomalies that signal early-stage battery degradation, far beyond the sensitivity of classical sensors.

Composite & Pipeline Integrity

Use Atomic Magnetometers to inspect aerospace composites or pipelines for corrosion and delamination without requiring physical contact.

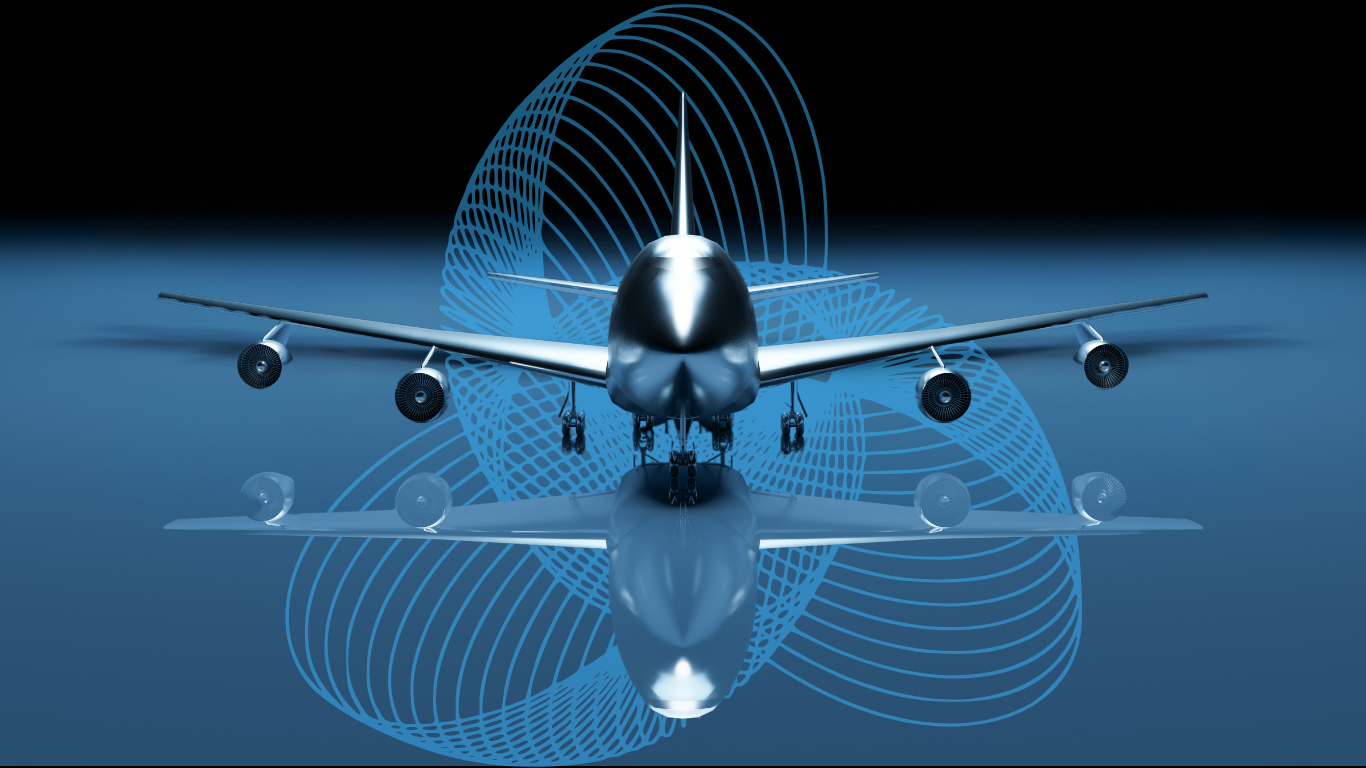

Navigation Resilience (Aerospace & Defense)

Advise on integrating ‘GPS-free’ navigation systems using Cold-Atom Gyroscopes, critical for autonomous systems in jammed environments.